IRB (Inflatable Rescue Boat) Operation and Maintenance

Equipment Inspection:

Pre-Use Checklist:

Fuel: Before starting the engine, check the fuel tank to ensure it is full enough and the fuel mixture ratio is correct.

Fuel System Inspection: Check the fuel tank connector, fuel lines, engine connector, and fuel line up to the carburetor bowl for any leaks.

Propeller: Inspect the propeller blades for cracks or bends. Check that the propeller nut and cotter pin are secure.

Spark Plug: Check the spark plug for cleanliness and proper gap. Dirty or improperly gapped spark plugs can negatively affect the engine.

Post-Use Inspection: After use, check the propeller and exterior of the engine for any damage.

Outboard Engine Installation Precautions:

The outboard engine can be carried by one person on their shoulder to the inflatable boat. Loosen the screws on the transom bracket, position the engine, and then tighten the screws. Secure the engine with a steel cable through the handle to prevent it from falling into the water if the screws loosen during operation.

After installing the outboard engine, start it to check if the cooling water outlet is functioning correctly and to inspect the engine's horsepower output at different throttle positions. Only begin operating the boat if all parts are functioning correctly.

IRB Operation and Seating Positions:

The outboard engine operating position (left or right) depends on individual preference. When starting, hold the throttle with one hand and pull the starter cord with the other.

Seating positions (single or multiple occupants) are determined based on the need for the balance and speed during rescue operations.

IRB Operating Techniques:

When approaching a drowning victim, the rescue boat should proceed upstream from the downstream position. The rescuer on board directs the driver on the direction of movement.

After the rescuer grabs the victim, they use their body weight to pull the victim into the boat.

Once the victim's body is inside the boat, the driver can assist. After the victim is completely inside the boat, accelerate away from the area.

If the rescue attempt fails, circle around the victim and position the boat downstream before attempting another rescue. Avoid turning the boat's stern near the victim or chasing the victim from upstream.

Boat Landing Precautions and Operating Techniques:

The driver should select a suitable landing spot before approaching the shore.

When approaching the shore, be aware of the distance between the outboard engine and the riverbed to prevent the propeller from striking rocks or submerged objects. Be mindful of sharp objects on the shore to prevent boat damage.

When approaching the shore, reduce the throttle to a slow speed and maintain an appropriate distance from the shore. Put the engine in neutral and allow the boat to glide onto the shore slowly.

If necessary, raise the outboard engine to the fixed position to prevent it from getting stuck in the mud. Secure the mooring rope firmly to the shore.

Outboard Engine Removal Techniques:

Remove the fixing screws on the transom board and loosen the locking screws on the outboard engine mounting bracket. Lift the outboard engine vertically from the boat to the shore, supporting it with the skeg. Use both hands to keep the outboard engine upright on the ground. Drain all remaining water from the engine. Be careful not to damage the propeller during transport. Ensure that the cylinder head is higher than the propeller.

Personnel should stand in a stable position. Ideally, two people should perform the lifting operation, with synchronized movements. Quickly inspect for any debris in the cooling water intake and any foreign objects on the propeller.

Outboard Engine Flushing and Fuel Tank Removal:

Disconnect the fuel line connector on the engine and allow the engine to run until it stalls to use up any residual fuel in the carburetor. This prevents fuel leakage during transport and avoids gasoline from evaporating and becoming difficult to start.

The engine itself should be flushed with fresh water to remove salt water or dirt to prevent corrosion.

During fresh water flushing, re-check that the cooling water intake and outlet are working normally.

Check that the quick connectors on the fuel lines are functioning correctly and that they move smoothly without being affected by sand or rust. Lubricate if necessary.

Cover the quick connectors on both sides of the fuel line with appropriate items to prevent dust from entering when storing.

Outboard Engine Storage:

The outboard engine should be stored upright using a mounting bracket, not lying on the ground.

Apply lubricating oil to maintain the internal parts of the engine.

Wipe the exterior of the outboard engine to keep it clean.

Apply grease to the grease fittings after use.

The outboard engine should be stored in a place that is not easily exposed to sunlight and where outside air circulates.

Use an protective case to protect the engine.

IRB (Inflatable Rescue Boat) Operation and Maintenance

IRB (Inflatable Rescue Boat) Operation and Maintenance

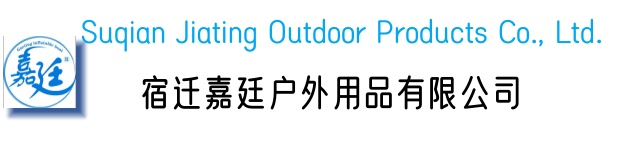

Safety Standards for Inflatable Boats

Safety Standards for Inflatable Boats

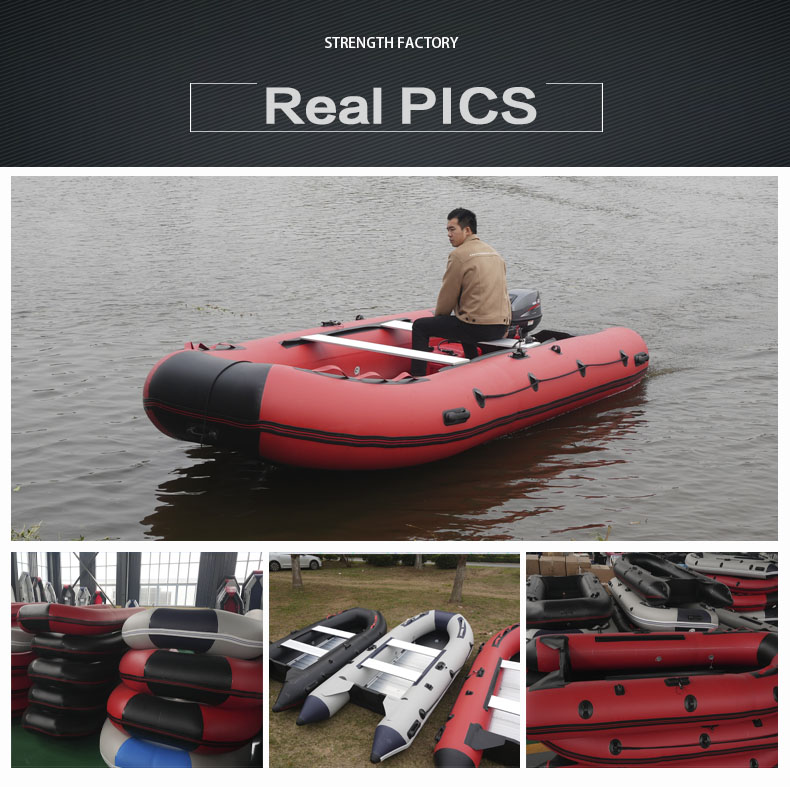

Securing Your Inflatable Fishing Platform: Enjoy a Stable and Worry-Free Fishing Experience

Securing Your Inflatable Fishing Platform: Enjoy a Stable and Worry-Free Fishing Experience