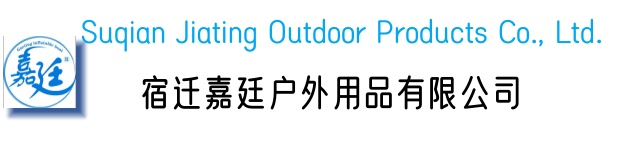

Water Rescue Equipment - Inflatable Boat

I. Installation and Disassembly

Installation Inspection

Caution: Ensure the valves are closed before inflating. The safety valve will automatically release air when over-inflated to protect the inflatable boat.

Before installing or disassembling the inflatable boat, clear away any nearby sharp objects.

Unfold and flatten the boat. The optimal temperature for this is above 16°C (61°F).

Verify that the valve stem on the air nozzle is closed. Press down and rotate counter-clockwise until the valve stem protrudes.

Floorboard Installation

Caution: The board surface must face up when installing floorboards! Partial inflation may be necessary to ease installation.

The #1 floorboard must be accurately positioned in the bow, and the position of the keel air nozzle must be adjusted.

The #4 floorboard is installed in the stern.

The #3 floorboard is installed in the buckles of boards #1 and #4.

The #2 floorboard and board #3 must be positioned correctly and pressed firmly downward to stabilize.

Inflation and Deflation

Caution: Do not use a tire inflator to inflate, as the strong airflow can damage the boat's seams and waterproof membrane!

Use the included foot pump or an electric pump with adjustable pressure and a switch to inflate. The air pressure should be according to the manufacturer's instructions. Use the pump correctly and avoid excessive force.

The maximum air pressure is: 3.5 psi (0.25 bar) for the hull and 5.5 psi (0.35 bar) for the tubes.

During inflation and deflation, each air chamber should be inflated or deflated evenly to avoid damaging the exhaust valves.

Disassembly

Caution: The boat hull must be clean and dry.

Open all valves, press down the valve stem, and lock it clockwise.

Use the foot pump to extract all the air from each air chamber of the boat.

With the boat bottom facing down, fold both sides of the boat towards the hull, then fold from the bow towards the stern.

Store the boat in a clean, dry place, taking care to protect the hull from sharp objects.

Cleaning Precautions

All boat fabric can be cleaned with soap and water. PVC fabric is coated with a UV protection layer before leaving the factory.

Do not use cleaning agents containing vinyl solvents, chemicals, chlorine, or gasoline to clean the hull.

Applying a UV protectant spray to the entire boat every six months (available at marine supply stores) can extend the inflatable boat's lifespan.

II. Operation and Use

Preparation Before Operation

Each operator should wear a life jacket or have floating equipment readily available.

Before using the inflatable boat, basic equipment such as oars, inflation pump, etc. must be fully prepared.

Do not overload the boat, and the outboard engine power must not exceed the manufacturer's requirements.

The weight on the boat must be evenly distributed. When using an outboard engine, do not accelerate or decelerate suddenly, as this may cause the hull to rupture.

Improper use of the outboard engine can easily cause injury or even death. Do not use an outboard engine that the boat is not designed to handle. When using an outboard engine, be careful of swimmers in the vicinity, do not approach them, and do not allow swimmers to approach the boat, especially the stern.

Pay attention to the wind direction, wind speed, and tide when using the boat, as these will affect the outboard engine's fuel consumption.

Before setting off into unfamiliar waters, it is essential to understand the water flow conditions.

Outboard Engine

Warning: Do not exceed the specified pressure! Overpressure can lead to serious handling or stability problems.

Use the kill switch lanyard. If any situation occurs, this switch will stop the engine. The operator only needs to pull the cord.

When rowing, everyone must sit on the seat boards, not on the edge of the boat, to prevent falling into the water.

Regularly check the screws on the motor. Loose screws can lead to boat instability and can also damage the outboard motor.

Be careful that objects piled on the deck do not puncture the boat skin.

Towing - Anchor - Mooring Rope

When an inflatable boat is being towed by another boat, no one should be sitting on the inflatable boat. The tow rope must be securely fastened to the D-rings on both sides of the inflatable boat. The mooring rope must be securely fastened to the D-rings.

If an air chamber fails, shift the weight to the opposite side. Tie up or hold the leaking area, and quickly paddle to the nearest shore.

III. General Troubleshooting and Repair

Repair Procedures

Small tears, cuts, and small hole repairs: For repairs of small holes or small tears less than 1/2 inch (12.7 mm), a circular patch with a minimum diameter of 3 inches (76.2 mm) is required.

The patch and boat surface must be dry, free of dust and grease.

Release the air from the boat and ensure that the cut or tear lies flat on the ground.

Apply three thin coats of adhesive evenly to the boat and the patch. Allow five minutes between each coat. After applying three coats, wait ten to fifteen minutes before attaching the patch to the damaged area on the boat. Heat the patch with a hair dryer to soften the adhesive if desired. Roll the patch firmly in place with a hard roller.

Do not inflate the boat until at least 24 hours have passed.

Large-scale boat repairs, such as seam damage, waterproof wall damage, and transom damage: For large-scale repairs, it is recommended to take the boat to a qualified inflatable boat repair center.

Safety Standards for Inflatable Boats

Safety Standards for Inflatable Boats

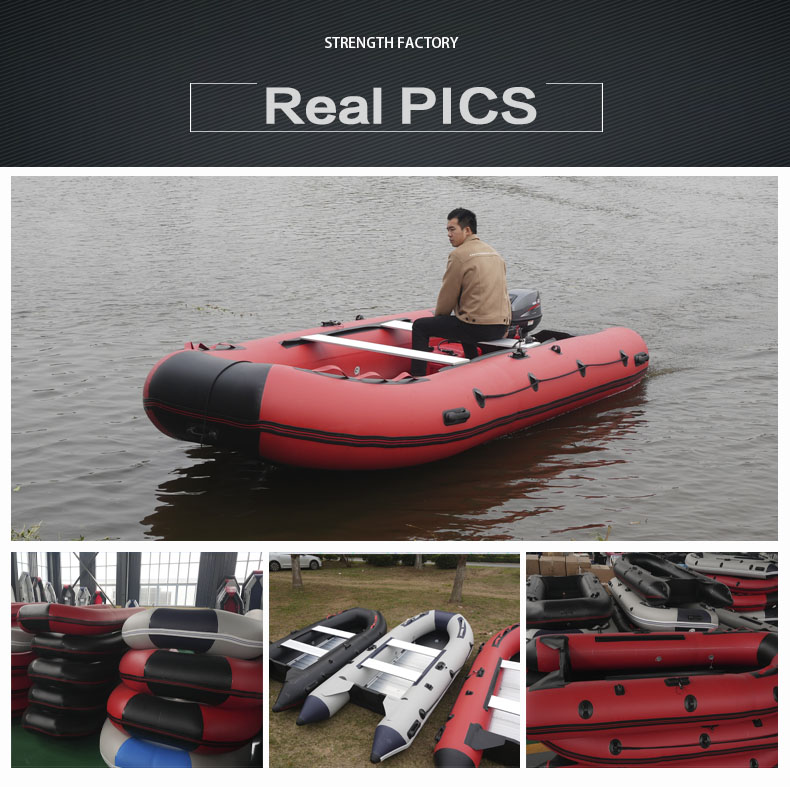

Securing Your Inflatable Fishing Platform: Enjoy a Stable and Worry-Free Fishing Experience

Securing Your Inflatable Fishing Platform: Enjoy a Stable and Worry-Free Fishing Experience

Outboard Motor Propellers: Finding the Right Manufacturer and Saving Time

Outboard Motor Propellers: Finding the Right Manufacturer and Saving Time

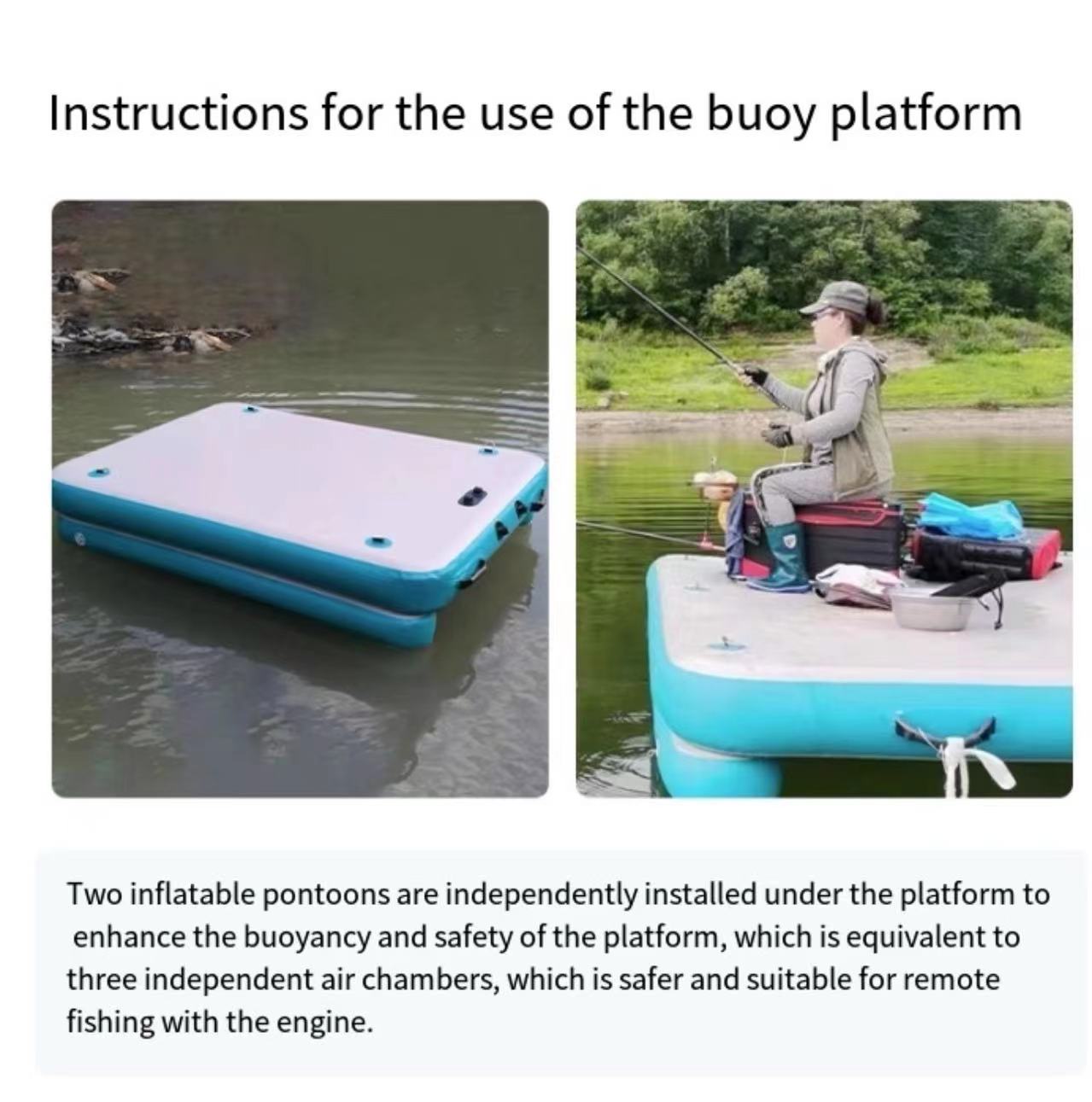

Paddle Board Fishing: A New Outdoor Adventure

Paddle Board Fishing: A New Outdoor Adventure